FAQS

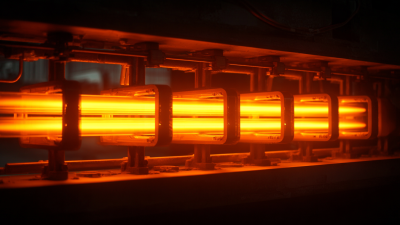

Exploring the Science Behind Industrial Heaters: How They Transform Energy into Heat

Industrial heaters play a critical role in various sectors, transforming energy into heat to meet the demanding requirements of processes such as manufacturing, food production, and chemical processing. According to a report by MarketsandMarkets, the global industrial heating market is projected to reach approximately $50 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.2% from 2020. This growth is driven by the increasing need for efficient thermal management in industrial applications. Understanding the underlying science of industrial heaters—ranging from electric heaters and gas-fired models to advanced thermal systems—enables businesses to enhance energy efficiency, reduce operational costs, and support sustainability initiatives. As industries continue to evolve towards automation and smarter technologies, the adoption of innovative heating solutions is more critical than ever to optimize performance and maintain competitiveness in today’s market.

Understanding the Basic Principles of Energy Conversion in Industrial Heaters

Industrial heaters play a crucial role in various sectors by converting energy into heat, a process grounded in fundamental principles of thermodynamics. Energy conversion in these heaters typically starts with electricity, gas, or oil as the input energy source. For instance, electric heaters utilize resistive heating, where electrical current passes through a resistance element, generating heat due to the Joule effect. This method efficiently transforms electrical energy into thermal energy with minimal energy loss, making it ideal for precise temperature control in industrial applications.

In contrast, combustion-based industrial heaters rely on the chemical energy of fuels. When fuel burns, it releases heat through exothermic reactions. This thermal energy then heats up fluids or air circulating within the system, resulting in effective thermal transfer to the environment or processes requiring heat. Understanding these energy conversion principles is vital for optimizing heating systems, enhancing efficiency, and minimizing environmental impact. The selection of an appropriate heating method depends on factors such as energy source availability, cost-effectiveness, and specific application requirements.

Exploring the Science Behind Industrial Heaters

| Parameter | Value | Unit |

|---|---|---|

| Input Energy | 5000 | kW |

| Heat Output | 4800 | kW |

| Efficiency | 96 | % |

| Heat Transfer Medium | Water | - |

| Operating Temperature | 150 | °C |

| Cooling Method | Forced Air | - |

| Control System | Digital Controller | - |

The Role of Thermal Conductivity in Heat Transfer Efficiency

Thermal conductivity is a crucial parameter in understanding how industrial heaters operate effectively. It refers to the ability of a material to conduct heat, which plays a significant role in heat transfer efficiency. In industrial applications, materials with high thermal conductivity, such as metals, are often used for heating elements. These materials facilitate rapid energy transfer from the heating source to the surrounding environment, ensuring that heat is efficiently distributed throughout the targeted area.

Thermal conductivity is a crucial parameter in understanding how industrial heaters operate effectively. It refers to the ability of a material to conduct heat, which plays a significant role in heat transfer efficiency. In industrial applications, materials with high thermal conductivity, such as metals, are often used for heating elements. These materials facilitate rapid energy transfer from the heating source to the surrounding environment, ensuring that heat is efficiently distributed throughout the targeted area.

Additionally, the design of the heater must consider the thermal conductivity of surrounding materials, as well as the medium being heated. For instance, in a fluid heating system, the thermal conductivity of the fluid determines how well the heat is absorbed and distributed. Enhancing the thermal conductivity of insulating materials around the heater can further improve efficiency, minimizing heat loss and ensuring more energy is converted into usable heat.

Consequently, optimizing thermal conductivity is essential for maximizing the performance of industrial heaters, making them more energy-efficient and cost-effective in various operational environments.

Comparative Analysis of Different Types of Industrial Heaters

The global heating equipment market is witnessing substantial growth, with projections indicating an increase from $115.57 billion in 2025 to $171.75 billion by 2032, representing a CAGR of 5.8%. This robust expansion is driven by the rising demand for efficient heating solutions across various industrial applications. A comparative analysis of electric and gas heating options reveals critical insights for industries looking to optimize energy costs. While electric heaters are often viewed as more convenient and environmentally friendly, gas heating systems can provide a more economical solution in specific contexts, especially in light of fluctuating energy prices.

In addition to conventional heating methods, the market is seeing advancements in the development of innovative technologies, such as solar air heaters with enhanced performance metrics. For instance, recent studies have evaluated the energetic and exergetic performance of solar air heaters utilizing winglet-type roughness on absorber surfaces, showcasing their potential in energy conservation and efficiency. The indoor space heater market is also on an upward trajectory, with forecasts estimating a growth to $23.2 billion by 2035, further highlighting the diverse needs and preferences of both consumers and industries seeking effective heating solutions.

Impact of Design and Materials on Heat Generation and Distribution

In the realm of industrial heaters, the design and materials used play a pivotal role in the efficiency of heat generation and distribution. Advanced materials, such as particle-filled composites, have been shown to enhance effective thermal conductivity, a critical parameter that influences how heat conducts within these systems. A recent study indicates that optimized composite materials can significantly improve thermal management, which is increasingly relevant given the rising power densities in various applications, from semiconductor technologies to large-scale energy systems.

Moreover, as urban heat islands continue to challenge community well-being, the integration of innovative heating solutions becomes paramount. Research highlights that heat recovery technologies can alleviate the urban heat island effect by capturing excess heat from surfaces like roads. Such advancements in thermal infrastructure not only reduce localized warming but also contribute to energy sustainability by transforming waste heat into usable energy, thereby addressing both environmental and energy efficiency concerns in industrial settings.

Advancements in Technology Enhancing Industrial Heating Systems

Recent advancements in technology are significantly enhancing industrial heating systems, particularly through the adoption of innovative heat pump technologies. The industrial heat pump market is poised for substantial growth, projected to reach USD 3,500 million with a compound annual growth rate (CAGR) of 11.7% from 2025 to 2035. This surge is largely driven by the increasing focus on reducing carbon emissions and maximizing energy efficiency in industrial operations. The ability to utilize waste heat effectively is becoming a crucial component in the design of sustainable industrial processes, pushing the sector towards greener solutions.

In addition to heat pumps, the trend of industrial electrification is gaining momentum, with expectations of the market surpassing USD 95.79 billion by 2034. This electrification is paramount for integrating advanced technologies that not only improve energy efficiency but also lower operational costs. Upcoming workshops and expos, such as the AHR Expo, highlight these innovations, showcasing the latest developments in heating systems. With emerging trends in thermal energy storage mechanisms and the integration of artificial intelligence in energy management, the industrial sector is on the cusp of a transformative shift towards more sustainable heating solutions.

Advancements in Industrial Heater Efficiency

This chart illustrates the efficiency improvements in industrial heaters over the years, reflecting advancements in technology that enhance energy conversion to heat.

Related Posts

-

Unlocking Warehouse Heaters Market Trends at the 138th Canton Fair 2025 in China

-

How Electric Space Heaters Can Reduce Your Heating Costs by Up to 50 Percent This Winter

-

How Infrared Bar Heaters Work: The Science Behind Efficient Heating Solutions

-

Unlocking Industrial Efficiency: The Science Behind Infrared Heating Technology

-

Optimal Warehouse Heating Solutions for Enhanced Energy Efficiency in Cold Storage Facilities

-

Maximize Your Outdoor Comfort: The Benefits of Propane Patio Heaters in Year-Round Use

Skip to content

Skip to content